Alfaholics Anonymous

![]()

During July I bought a ratty Alfa 75 for NZ$1500. No rego, no warrant, no brakes, and no clutch. However it was the correct colour so I was forced to buy it.

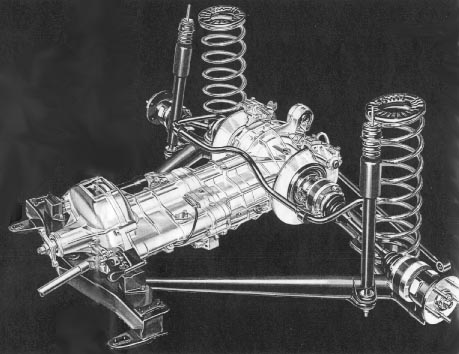

I replaced all the brake disks and fitted new rear brake pads (since all that remained was metal). A new clutch was also inserted. An Alfa 75 clutch is *oh* so much easier than a GT-Four. Basically unbolt the front of the de-dion rear suspension triangle and angle down the front of the transaxle. The clutch is in a housing at the front of the gearbox and can simply be unbolted and slid off. Biggest problem is having to hacksaw through the seized solid rear exhaust instead of slipping it apart as intended.

|

|

| This photo was taken in 1992. Before I owned it, well duh... obviously it was a little bit shinier back then. | And now, scruffy as hell. |

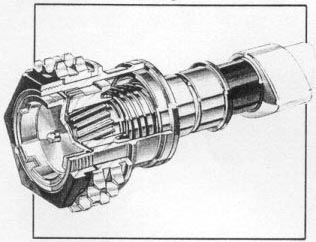

The car has a 2.0 litre twin cam two valve engine. Only two valves per cylinder, but these are BIG valves! It uses Bosch Motronic EFI and has variable valve timing on the inlet cam, yes Alfa had this way back in the mid 80's. At the time it wasn't even mentioned in their press releases. A diagram is shown below. The ECU activates a solenoid plunger which plugs a hole in the centre of the camshaft, causing oil pressure to rotate a sleeve a set amount, changing the cam position.

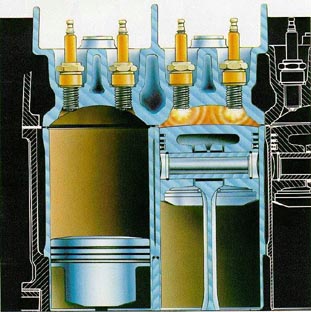

The engine also uses two spark plugs per cylinder to improve ignition by having two flame fronts. This requires two distributors.

Some aspects of the engine design are very well done. This is an evolution of the classic Alfa twin cam engine which has been around since the 60's. Some other aspects of the engine make you wonder what they were smoking when they designed it...

The handling of the car is best described as absolute crap. The 14" alloys and rock-hard tyres have been swapped for some suitable 15" Ronal alloys and new Dunlop FM901 tyres, as shown on this 75 below. Bilsteins have been imported from the US (half the local price) and I'll also do all the rear bushings in urethane, some of the front having already been done. I'm looking to source lower rear springs and a thicker V6 front sway bar (24mm vs 22mm). I'd prefer larger torsion bars but they are out of my budget, this is supposed to be a cheap car! A picture of the rear transaxle is also shown.

Now when I initially checked the car out it was rustfree. It developed rust in several places on the towtruck ride home unfortunately :-( Further investigation (and discussion with a previous owner) revealed a front quarter had been replaced after an accident in the early 90's. The rust I found was all down the heat affected zone of the welds where the quarter was welded in. There was also some rust in the front quarter, having been imported from the UK. I removed the guards and got stuck in with a wire brush in a grinder, stripping away paint and rust. Any holes now have plates welded over them (thanks Phil) and lots of Epiglass PA10 to hold the red rot off for a while. The rest of the car is remarkably sound. It should be good for a number of years yet. One day when enthusiastic I need to devise a way to spray rust converter and sealer into the chassis rails.

I've stripped the intake manifold off, checked all water hoses and replaced the thermostat. All fuel lines have been replaced with high-pressure fuel hose. The leaky camshaft cover was resealed and all valve clearances checked. The engine appears to be in good nick for 155000 kms.

Once the suspension changes are done I hope to get it out on the racetrack.

So what is it like to drive? I won't comment on handling till it is sorted but the engine is great. 4000-6000 rpm is excellant, love those Alfa top-end cams! The exhaust centre muffler is paper thin so I need to replace the exhaust, hopefully with something slightly less restrictive. I want to keep that Alfa symphony though.

UPDATE: The exhaust has been replaced from the bottom of the cast headers to the rear axle. It was done by Pitstop in Manukau (only because they were handy) and the manner in which the work was done is best described as piss-poor. They were instructed to replace the exhaust from the bottom of the cast headers to the rear axle (where a flange was to be installed). It came back with the exhaust replaced from the secondary collector to the rear axle without the flange (intended to allow gearbox removal). Well the car went back and they did what was asked in the first place. However the secondary collector is very poorly crush-bent and a bad impedance to flow. They put the flange in, but did so by simply cutting a shitty flange out of an old exhaust and welding it in. To top it off the exhaust also bangs underneath, but I refuse to take it back for them to stuff it up even more! Buyer beware!

I've taken a number of engine pics in various states of disassembly and will post them here once scanned.

![]()

![]()